OUR EXPERTISE

Headspace Analysis (O₂ & CO₂ TDLAS)

Our laser-based headspace analysis supports two key applications:

- CO₂ tracer gas testing for deterministic, non-destructive CCIT — we like to call it “Blue Dye 2.0.”

- O₂ is important for lyo customers, and with our Christ Pilot Epsilon 2-4 we can simulate the process including the closure with the correct gas phases and pressures.

- With O₂-TDLAS we can additionally offer to test containers for residual oxygen concentrations

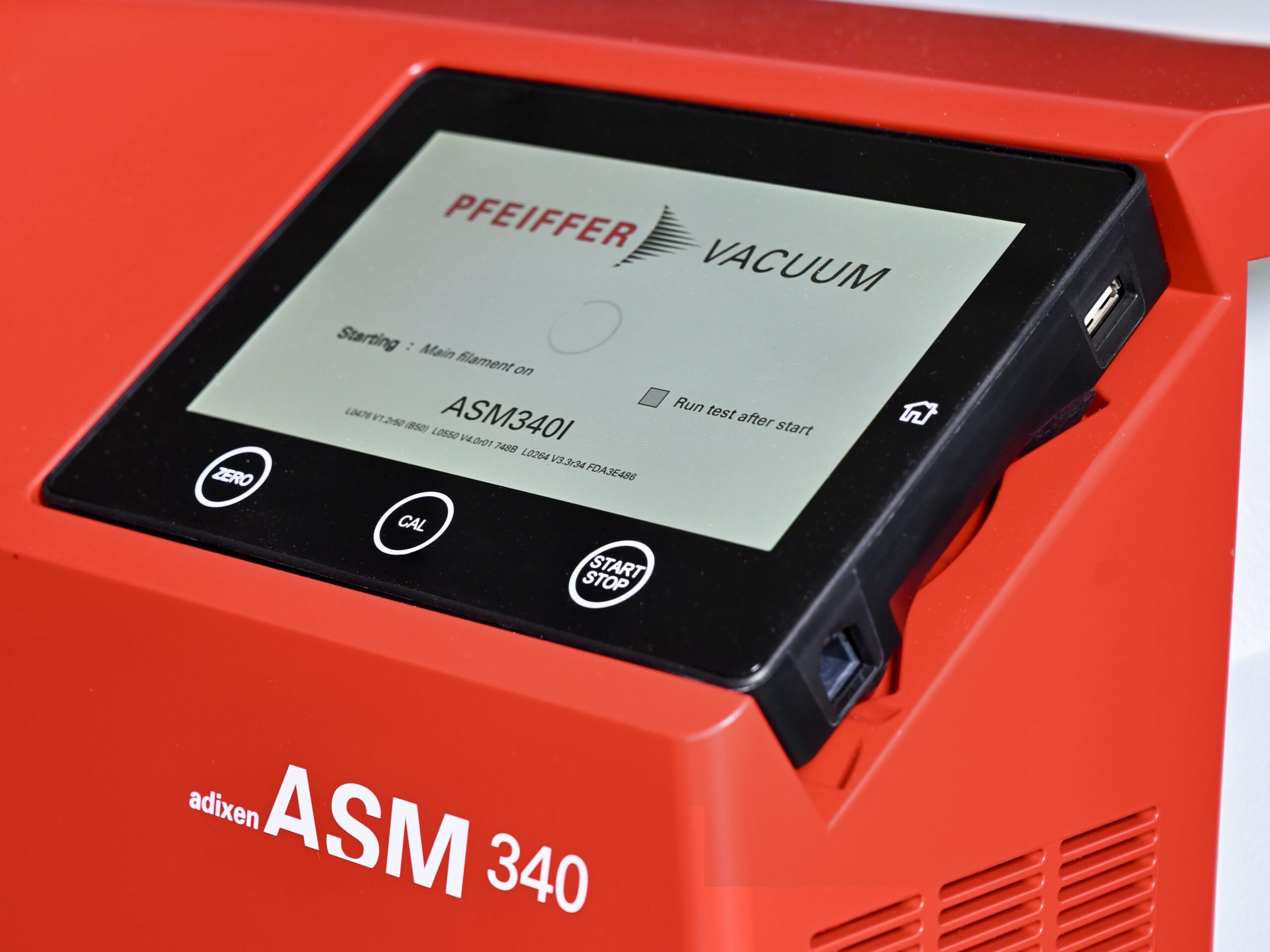

Helium Leak Testing (HLT)

The most sensitive CCIT method, based on mass spectrometry. Valuable for:

- Verifying artificial defects

- Packaging development

- Complementing CO₂ CCIT when maximum sensitivity is needed

Residual Seal Force (RSF)

A support technology for vial/stopper systems. While not an integrity test itself, it provides valuable insight into crimping consistency, signals when maintenance is required, and in some justified cases can support reduced CCIT frequency.

Artificial Defects

Essential tools for method development and validation. We provide:

- Laser-drilled defects

- Capillary inserts

- Stopper and closure defects

- Glass cracks

- Stopper height variationsAll defects are characterized by HLT to ensure reproducibility and traceability.

Lyo Closure Simulation

Lyophilized parenteral packaging carries a specific and often misunderstood risk: closure disruption during the transition from freeze drying to crimping. After lyophilization, containers are transported under Grade A conditions — if stoppers are only partially seated and not yet crimped, they can allow for gas exchange. While the risk for microbial contamination is low, approximately 0.5% of containers may lose vacuum and ingress oxygen or moisture — impacting stability. We simulate this phase to analyze and prevent hidden failures.

Annex 1 Aligned Studies

We provide Annex 1–relevant studies, including:

- Transport & storage simulations

- Stability testing with integrated CCIT

- Residual vacuum verification for lyo containers

- Headspace O₂ analysis & oxidation studies

- Inspection readiness & documentation support

Method Development & Validation

We execute method development and validation in our labs, including artificial defects and sensitivity challenges, and deliver fully regulatory-ready documentation in line with Annex 1, USP <1207>, and FDA guidance.